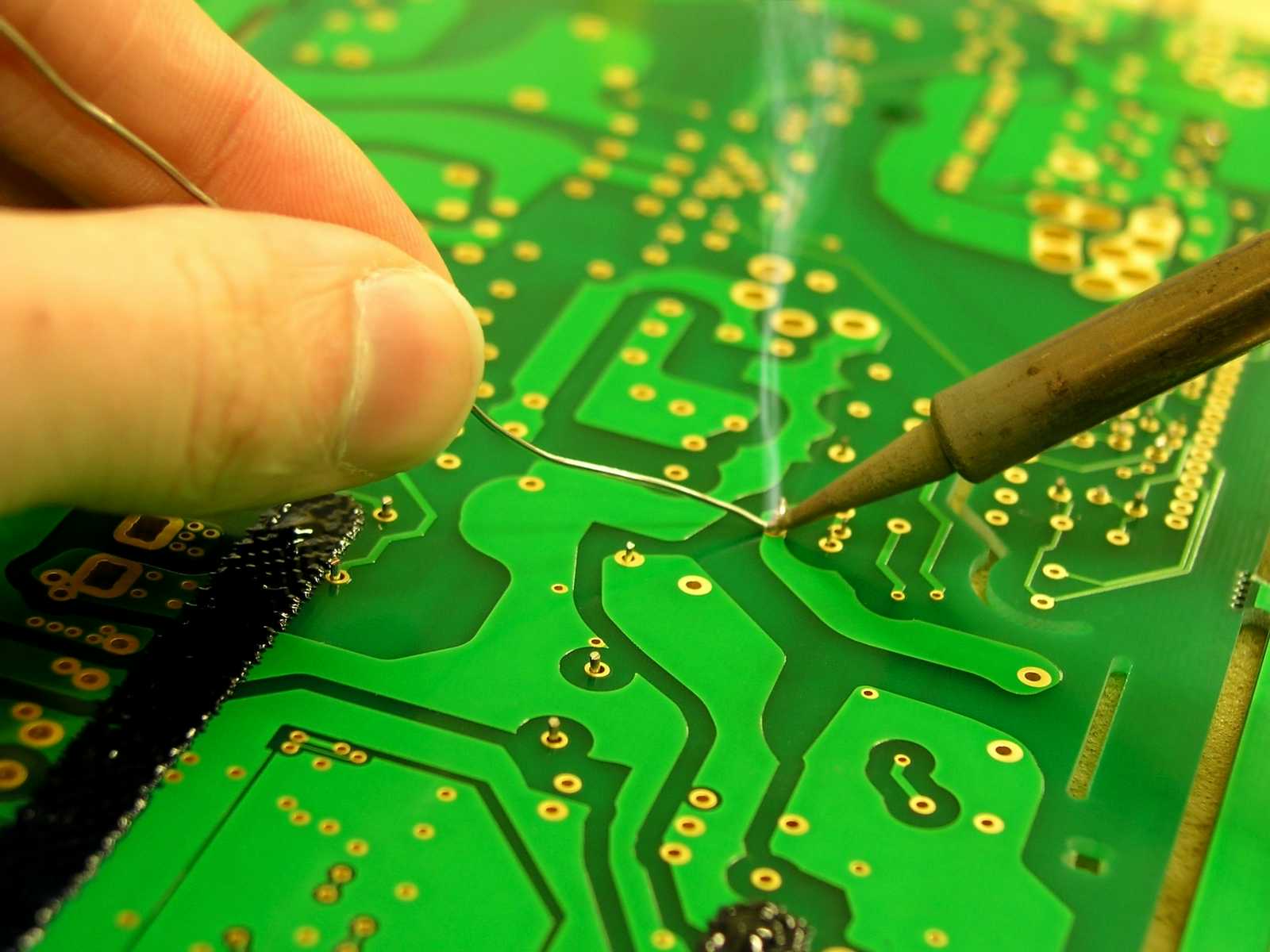

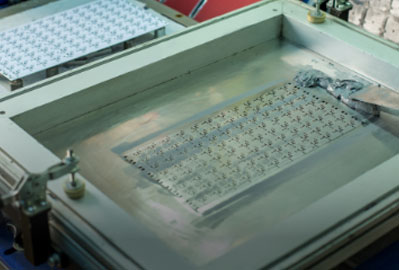

If you work in the nearly 1 trillion dollar engineering industry, you already know the importance of frequent circuit board maintenance. Applying soldering paste to precise locations that require repairs would take a lot of patience and expert tools to do manually, but there's a great alternative for repairing your board: rework stencils. Keep reading to learn how rework stencils can help with board repair and ensure a perfect fit for your parts.