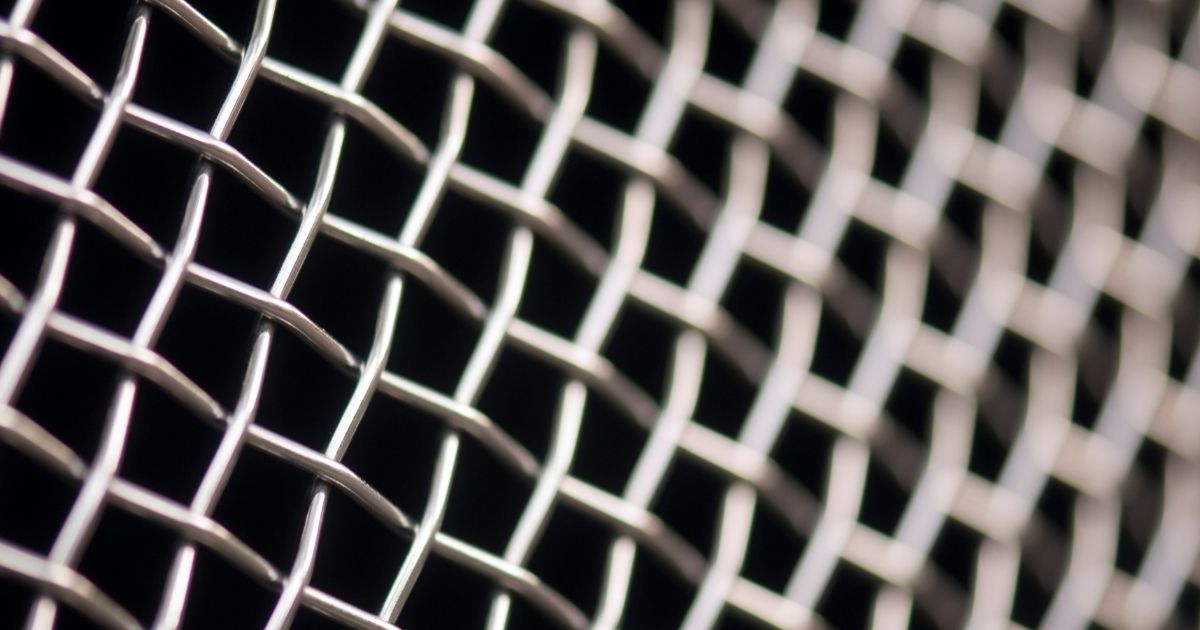

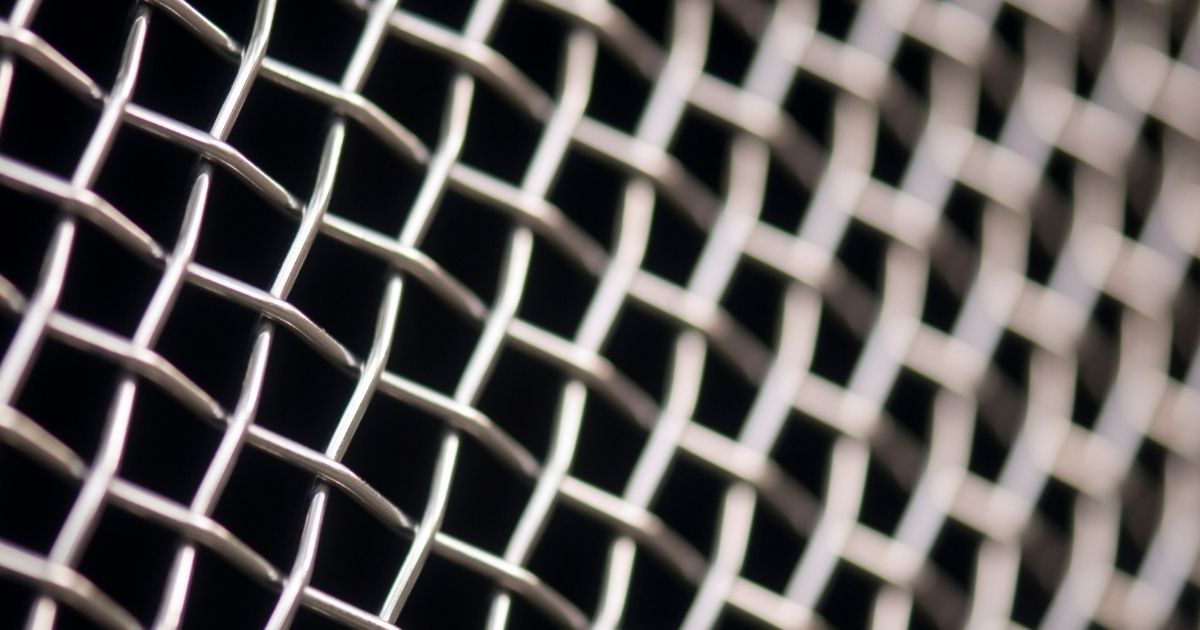

Understanding the raw materials used to create screen printing mesh is crucial for anyone in the screen-printing industry. The choice of raw materials has a direct impact on mesh performance, print quality, and durability. In this blog, we'll explore the most common raw materials used in screen-printing mesh and discuss their properties and advantages.