The world of microelectronics is highly technical, and it can be challenging to fully understand the details of each component. To help make this easier, we’ve compiled a list of frequently asked questions to provide information about some of the questions you might be wondering!

Stencils are used to print directly onto a PCB (on-contact printing). An image in a stencil consists of apertures (laser-cut, chemically etched, or electroformed) through a solid material, such as stainless steel.

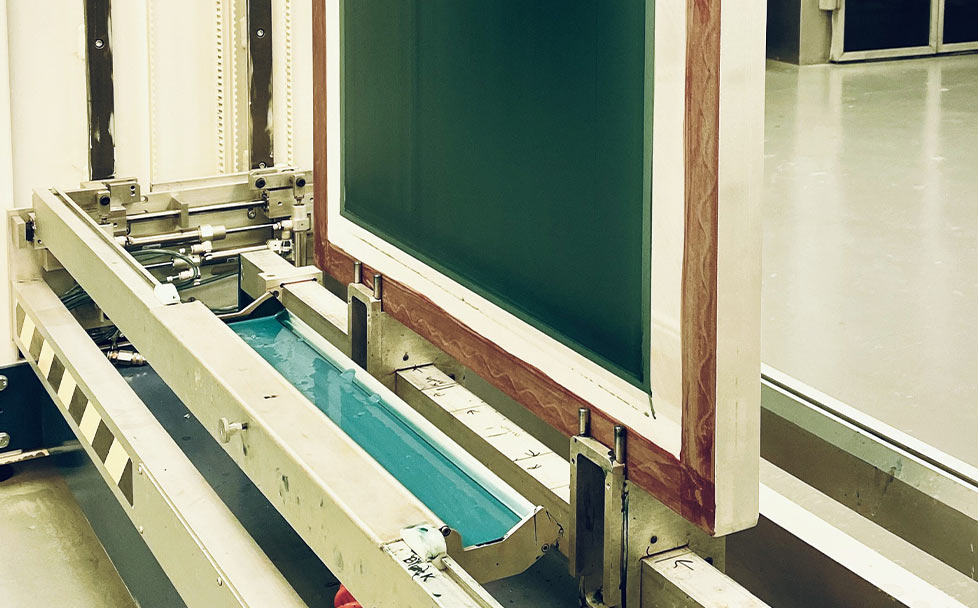

In screen printing, a fine weave of stainless steel or polyester mesh is coated with emulsion, and the image is then exposed with a camera or light source. Screens have a bit of separation (off-contact printing) with the substrate, allowing the mesh to contact the printed surface as the squeegee passes.

We can use Gerber, DXF, or ODB++ file formats.

A conformance report is shipped with every stencil. Upon request, a “paste report” that includes area ratio, aspect ratio, and volume can be provided at no extra charge.

We currently have files dating back to June of 2003. The MMSN number is unique to every stencil or screen and is the best way to reference any MicroScreen product. All data is kept in a corresponding directory.

Features down to .003” can be cut.

We offer two types of nanocoatings. MicroGlide is an affordable, two-part wipe that can be applied to any stencil—old or new—to improve solder paste release. MicroGlide Platinum is a heat-fused nanocoating that is excellent for ultra-fine pitch printing and will not flake or chip off.

We offer a pre-saturated, heavy-duty stencil cleaning wipe that will not tear or leave lint behind.

At the very least, a paste layer. If this isn’t available, we can create it using other layers. A check plot in Gerber or PDF will be sent for approval prior to fabrication.

Our technical experts can help with specific trouble areas to recommend proven component designs and modifications, foil thicknesses, and nanocoatings.

Many factors that vary with every stencil user make this question difficult to answer. According to IPC7525B Stencil Design Guidelines, Section 9 – End of Life, “Stencils should be inspected periodically for damage that would contribute to decreased printing performance.”

If other layers are panelized, we can panelize the paste layer. A drawing with measurements can be used to panelize the files; or, as a last resort, you can send us a PCB.

Yes, we can look at your application and make recommendations from that to determine the desired wet-print thickness.

Mesh equalization is the process of filling the mesh opening with emulsion and building up a thick enough emulsion to equalize or smooth out the surface structure of the mesh. Additional emulsion is applied to match a customer specified emulsion build up or overall screen thickness.

Our advanced stretching systems accept frame sizes up to 70” x 102” and provide consistent, exact duplication of tension from screen-to-screen and stretch-to-stretch on both stainless steel and polyester mesh.

Get in touch with our team today to learn more about the stencils and screens we offer!

Copyright © 2023 MicroScreen LLC. All rights reserved.