Nanocoating is a must for high volume stencil applications. Learn about the longest lasting nanocating on the market: MicroScreen's MicroGlide Platinum.

Nanocoating derives from the Greek word nanos, which means dwarf. Nano technology is so named because of its atomic-level size of 1–100 nanometers. One nanometer is equal to 10 millionths of a centimeter, which is about the width of three atoms.

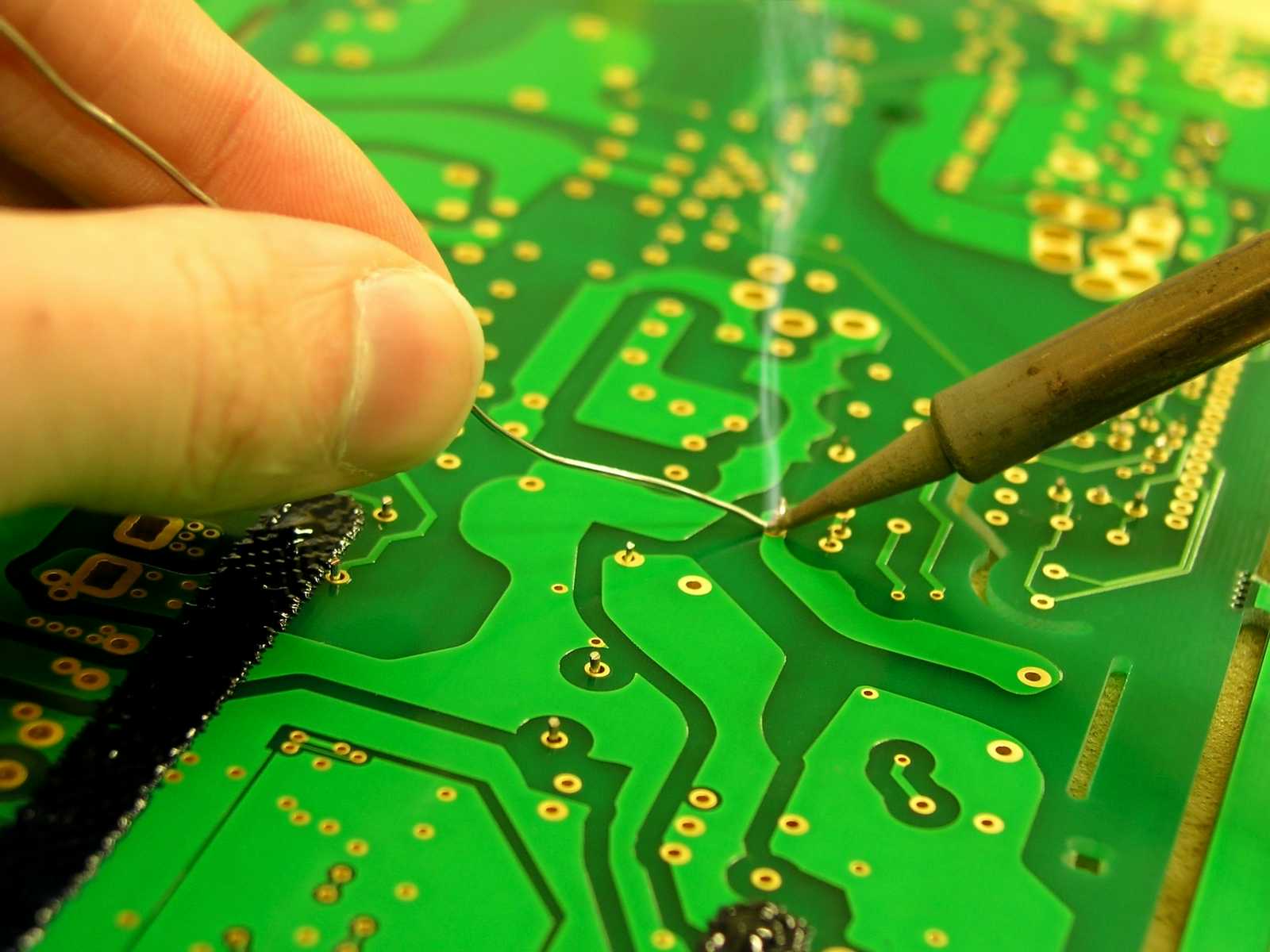

In printed circuit board (PCB) fabrication, componentsolder pads must be perfectly clean and without scratches. Coatings are sometimes used on the solder stencil to improve paste release from the stencil. It’s also important that any protective coating on the stencil does not decrease the amount of solder deposited on the component pads. The incredible smallness of nanocoating makes it a great option for PCB stencils and stencil manufacturing.

Advantages of Nanocoating

What do nanocoatings do?

Nanocoatings made their debut in the auto industry and have since expanded into many other areas. They can be used to cover large surface areas like boats as well as small surfaces like PCB components. Just as nanocoatings protect vehicles and outdoor items from weathering, they protect stencils from wear and prolong their lifespans.

Nanocoatings are both hydrophobic and oleophobic, which means they repel liquids and oils. The barriers nanocoatings create prevents corrosion, since moisture and oils cannot reach the metallic surface. By sealing the surface of the object against airborne particles of salt, they also protect against the effects of salt on metal.

How do nanocoatings support PCB fabrication?

In PCB applications, nanocoatings play an important role in preventing porosity, scratches, and the accumulation of fine dust. Additionally, they are highly heat resistant, which is key for safety, reliability, and performance. Nanocoatings are so heat-resistant that they are often used on patio furniture to protect it from stray sparks from a nearby grill!

Nanoparticles fill in uneven surfaces to create a smooth, continuous, invisible coating that has a durable chemical bond with the surface. A smoother surface reduces the chances that components will separate from circuit boards. Also, because nanocoating improves paste release and transfer efficiency, it allows you to print more boards between stencil washes. This reduces the frequency of needed cleanings, resulting in lower labor costs and improved productivity.

MicroGlide by MicroScreen

MicroGlide is a self-assembled monolayers phosphonate (SAMP). This type of coating consists of a layer one molecule thick and is applied with a two-part, single-use wipe. This is one of the most advanced coating on the market today. It is a true nanocoating, defined as one that is applied in single-digit nanometers.

MicroGlide Platinum by MicroScreen is an ultra long-lasting nano coating which is heat fused to the stencil surface and should last in most circumstances for the life of the stencil.

Benefits of MicroScreen MicroGlide Nanocoatings

Ease of Use

MicroGlide can be reapplied at any time. While the surface of the stencil should be clean immediately before application, it's not necessary to remove the old coating.

Durability

MicroGlide Platinum This unique nanocoating is incredibly durable, thin, and long-lasting. Because the nanomaterial is fused onto the stencil at a high temperature, it becomes strong and resistant to cracking and chipping. This coating can be several times harder than the material it's applied to!

Thinness

MicroGlide Coatings will not clog apertures or affect component size. Its extreme thinness renders the added mass practically negligible. As a result, there is no need to worry that it will contaminate flux as it wears off.

Reliability

MicroGlide Platinum improves print quality, repels flux, and ensures paste deposits easily and uniformly. It's highly accurate and reliable, which helps lower manufacturing costs, and it functions well in high heat.

Efficiency

Part of what makes MicroGlide Platinum ideal for PCB manufacturing is that it bonds well to stainless steel and features an excellent solder paste release. Application is quick, curing in just 15 minutes. A stencil nanocoating can take PCB manufacturing efficiency to the next level.

Longevity

In 2019, longevity testing was performed on stencils coated with MicroGlide Platinum. The results showed that after more than 88,000 prints, the stencil still had clean sidewalls and no solder balls. Furthermore, it was still high yield and had great paste transfer.

Lower quality nanocoatings have a lifespan of 9 months to 2 years, while the highest quality coatings last for 3 years or more. MicroScreen's MicroGlide Platinum comes with a 3-year guarantee.

Frequently Asked Questions About MicroGlide Platinum

Is the coating guaranteed?

Yes, the stencil has a 3-year full replacement guarantee. You can be confident that our product will hold up longer than competitors, and will require little maintenance.

Is additional lead time needed for this heat-fused process?

No, it can usually ship on the same day!

How do I know when to specify this coating?

The MicroGlide Platinum nanocoating is ideal for high volume stencils. A stencil coated with this technology can handle an exceptionally high volume without damage or significant dust accumulation.

Your Source for Stencils and Screens

At MicroScreen, we understand that stencil manufacturing requires a high level of accuracy, cleanliness, and reliability. To help you choose the best products for your business, we’ll conduct a free evaluation to determine the ideal stencils and nanocoatings for your applications. To learn more about microelectronics stencils, screens, emulsions, and more, subscribe to our blog!